Struggling with cost and scale in cultivated meat production? Our filamentous fungi-based platform improves protein content, meat-like texture, and overall process efficiency – while lowering production costs. The result: a bioprocess-ready solution that outperforms traditional cell culture in both scalability and cost-efficiency.

Background

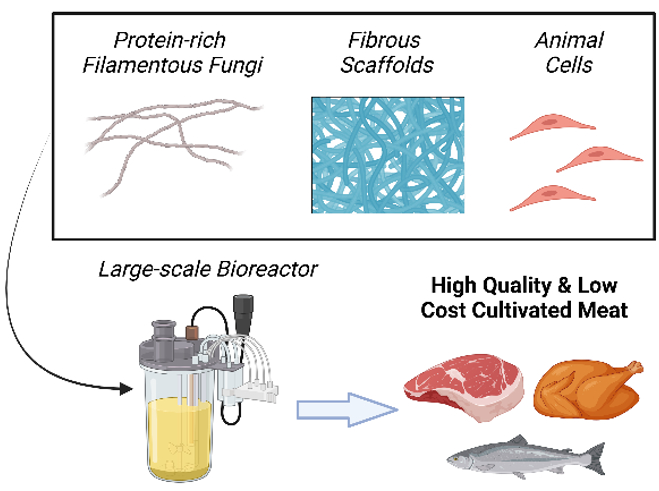

Cultivated meat is a promising technology for sustainable protein production, but achieving the desired protein content and meat-like texture requires intensive cell culture, resulting in high costs and scalability challenges. To address this, we propose incorporating filamentous fungi – naturally rich in protein and possessing a fibrous, meat-like structure – by integrating muscle cells into the mycelium using spaghetti-like scaffolds.

Technology

Our innovative technology integrates filamentous fungi into cultivated meat production, with research focused on optimizing this approach into a bioreactor-ready, cost-effective solution tailored for GMP compliance. This process involves fungal biomass processing, incorporation of fungi-derived components with muscle and fat cells into fibrous scaffolds, and bioreactor-based cultivation. We generate novel spaghetti-like fibrous scaffolds that ensure the desired texture as well as the ideal mass transport conditions for nutrient solutions to support cell growth. We use only the natural products alginate and chitosan, which can be directly used and degraded by fungi while still maintaining the distinct texture needed for cultivated meat. The use of highly porous fibrous scaffolds enhances cell adhesion and nutrient diffusion, facilitating seamless integration into the bioreactor environment. Unlike conventional methods that rely on thin-layer stacking or 3D printing, our approach enables scalable, cost-effective production by leveraging the structural and protein-rich properties of fungi. This flexibility allows for the use of various high-protein filamentous fungi, such as Fusarium venenatum and Aspergillus oryzae, optimizing both texture and nutritional value. Our methodology presents a promising breakthrough in cultivated meat manufacturing, promoting scalability, and sustainability.

Offer

Experts:

Prof. Dr. Sebastian Schwaminger, Dr. Vincent IrawanDevelopment status:

Status of the project proposal – Technology Readiness Level 3 (experimental proof-of-concept)Available for:

Investments, Joint Research Projects, Contract ResearchKeywords:

Filamentous fungi, Cultivated meat, Scaffold, Fusarium venenatum, Aspergillus oryzae, Nutrition, Texture, Cell-based proteins, Scale-up, Bioreactor

Image of Fusarium venenatum mycelium by Gemini