Next Generation Bioproduction

Disruptive Bioeconomy

In its strategic area, acib creates the basis for a disruptive bioeconomy along two main strategic high-risk thrusts that go beyond the state of research: CO2/H2-based bioeconomy and the supply of essential medicines through bioproduction in plant cells.

- Complete process technologies for large-scale production of food-and-feed products and biodegradable materials based on (waste) CO2 feedstock utilization by microbial gas fermentation

- Light-driven conversion of CO2 for specific production purposes

- Plant biotechnology for the future production of medicines

- Revolutionized production of metabolites from medicinal plants (e.g. opiates for pain therapy)

- Decentralized production of biopharmaceuticals

Renewable Resources

The Renewable Resources Area is mainly dealing with the industrial sectors of food and animal feed as well as materials, both of which have to solve important issues relating to the circular economy and resource efficiency.

- Improved agricultural production systems by microbiome functions

- Modular bioprocessing for (oligo)saccharide and C- and N-glycoside production

- Meat aroma for alternative protein food ingredients

- Novel functionalization of bio-based and biodegradable materials

- Closing the recycling loop for textiles and bio-based plastics

Sustainable Production

The Sustainable Production Area exploits novel strategies in bioproduction with the overarching aim to increase sustainability. Specifically, Sustainable Production utilises next-generation microbial cell factories and advanced biocatalysis in technologically feasible and environmentally friendly processes, and addresses various aspects of eco-friendly biomanufacturing and green chemistry.

- Innovative multistep-enzymatic cascade reactions

- Sustainable technologies for yeast-based recombinant protein production

- Microbial biotechnology and Synthetic Biology of yeast, bacteria and filamentous fungi

- Modular process development for peptides, aroma compounds, agrochemicals, components of energy storage

- Use of climate friendly substrates and valorization of waste streams

Health Biotechnology

The focus of the Health Biotechnology Area is on the development of production processes, the molecular characterization of novel biopharmaceutical products and the identification of new active pharmaceutical ingredients (API). In addition, the development of early diagnosis systems will enable a shift towards early prophylactic medical measures.

Natural and healthy meat flavour to make meat alternatives delicious!

Elevating skin care with algae ingredients

Chromatin as a critical impurity in virus purification

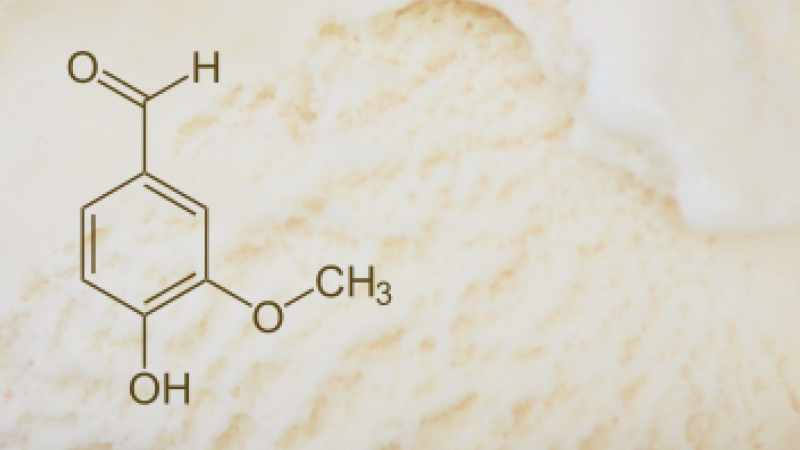

Shortest biocatalytic pathway to natural vanillin from eugenol or clove oil

Testing corona drugs on SARS-CoV-2 virus samples

Fermenting futures, yeast from an art perspective

Valuable proteins from CO2

Hope in the fight against global droughts

The COMET funding program

The COMET competence centers work with companies and research partners to develop solutions for future topics such as climate protection, digitization, mobility and health. This strengthens the innovation and business location and secures Austria a place among the leaders in international research and creates highly qualified jobs. The COMET competence centers are financed by the federal government – specifically the Federal Ministry Innovation, Mobility and Infrastructure and the Federal Ministry Economy, Energy and Tourism – and the federal states Styria (via the Styrian Business Promotion Agency, SFG), Vienna, Lower Austria and Tyrol. The Austrian Research Promotion Agency (FFG) has been responsible for professional program management for more than 20 years.

Interested in joining the COMET network?

Projects for and with company partners. At the moment all funding has been exhausted. However, any interested company from small to large and from Austria to international can express their interest to be put on the waiting list. Martin Trinker will be happy to advise you and to answer all of your questions.