The use of conventional plastics leads to an ever-increasing amount of environmental pollution and microplastic accumulation. A potential alternative to petroleum-based materials is lignin, a regrowing, sustainable and currently underutilized resource. An enzyme-based approach allows the production of 100% biobased materials.

Background

Conventional plastic packaging is one of the main contributors to environmental pollution. Despite the availability of biodegradable alternatives such as PLA or PHB, these biopolymers often fall short in terms of degradability under everyday conditions and involve complex production processes. In contrast, lignin – an abundant, regrowing and CO₂-neutral by-product of the paper and biorefinery industry – remains vastly underutilized, with only about 2% of the over 70 million tons produced annually being used in value-added applications. Its natural polymer structure and degradability under moderate conditions offer a unique opportunity to address the global plastic problem sustainably.

Technology

We have developed an enzyme-based process that enables the polymerization and functionalization of lignin for direct use in packaging applications. By enzymatically polymerizing lignin and optionally combining it with compatible biobased additives, the material becomes suitable for industrial processing techniques including film casting and extrusion. This innovative approach yields a 100% biobased packaging material that is biodegradable at average household conditions and can be tailored to specific performance requirements. In addition to being a sustainable alternative to fossil-based plastics, the material naturally possesses UV-absorbing, antioxidant and antimicrobial properties – beneficial for numerous packaging scenarios.

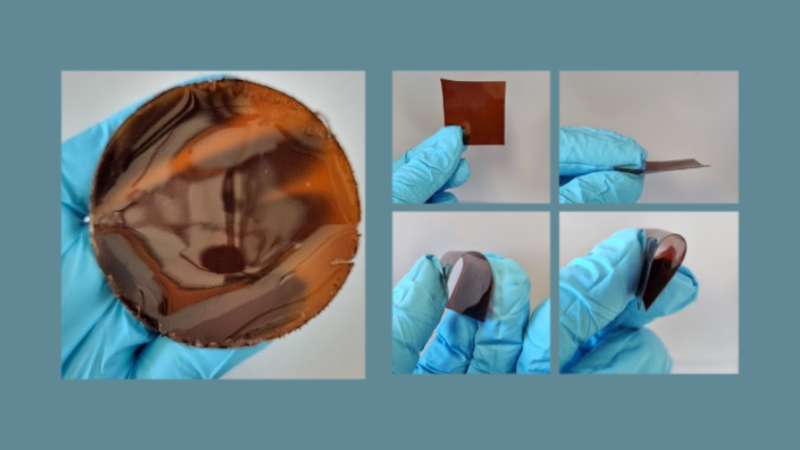

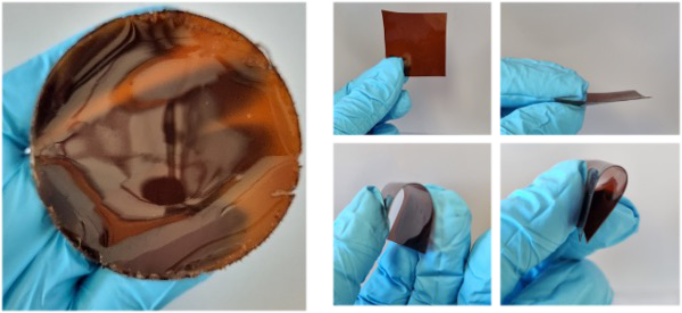

Figure 1: Casted and dried biomodified lignin film (left). Piece of a flexible biomodified lignin film, (right).

Offer

acib offers a versatile platform for developing sustainable packaging solutions based entirely on renewable resources. The biomodified lignin material is extrusion-compatible and adaptable to various end-use formats, from films to granulates. We are looking for industrial partners interested in co-developing and testing customized formulations for specific packaging applications.

Experts:

Dr. Sebastian Mayr, Prof. Dr. Georg GübitzDevelopment status:

Technology Readiness Level: 3-4IPR:

WO 2020/152314 A1Partners:

Institute of Environmental Biotechnology (BOKU)Keywords:

Biobased plastic for packaging, Lignin films, Biodegradation, Enzymatic process, Circular economy, Sustainability

Picture: Pixabay