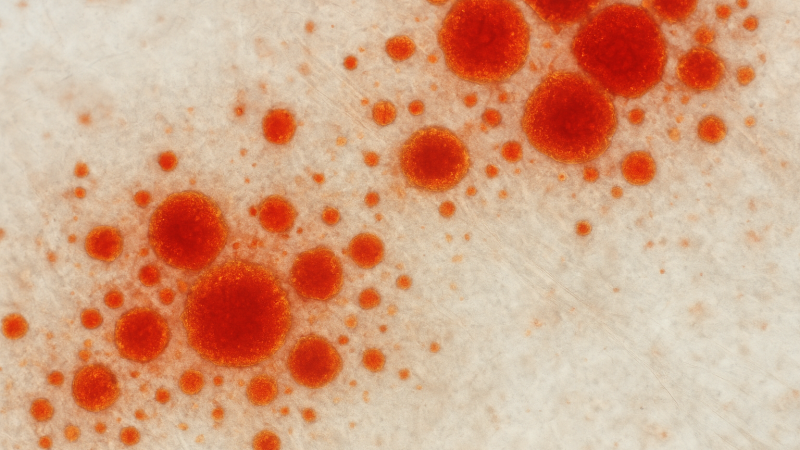

Plant-free Alizarin S for reliable calcium-staining: a sustainable microbial route from pathway discovery to purified diagnostic grade – built to de-risk supply, quality, and cost at scale.

Background

Alizarin S (Alizarin Red S; sodium alizarin sulfonate) is a benchmark stain for detecting calcium deposits and matrix mineralization across histology, osteogenesis, and tissue-engineering workflows, with standardized protocols and quantitative readouts used globally. Histor-ically derived from madder root and later displaced by chemical syn-thesis, it remains a staple reagent supplied by major vendors. At the same time, growing lab and diagnostic activity continues to expand demand for stains and reagents. Conventional dye manufacture car-ries well-documented environmental burdens from anthraquinone ef-fluents, reinforcing the case for cleaner production models. Emerging bio-based approaches – including engineered or elicited production of anthraquinones – offer a pathway to consistent quality, lower foot-print, and improved supply security for critical stains like Alizarin S.

Technology

acib aims to establish a microbial production platform for Alizarin S by elucidating the native plant pathway (RNA-sequencing, metabolic modelling), reconstructing the route in suitable bacterial and fungal hosts, and, where needed, replacing unknown steps with literature-derived alternative enzymes that perform the equivalent reactions. We’ll apply CRISPR-Cas and modern cloning for strain engineering, quantify titers by HPLC-(MS), and optimize a lab-to-pilot bioprocess including media, feeding/induction, and bioreactor parameters (1–5 L). Downstream focuses on efficient extraction and purification using sus-tainable, “green” solvents to deliver partner-testable material and a reproducible recovery workflow.

Offer

For industrial partners, we’ll establish a clarified biosynthetic route and gene set for Alizarin S; engineered microbial strains and a validated analytical method; an optimized 1–5 L fermentation concept with doc-umented process parameters; and a scalable downstream protocol yielding purified Alizarin S suitable for your internal QC and application testing. Work proceeds under NDA; project-specific results, data, mate-rials and IP can be assigned to you.

Collaboration can be tailored to your needs – from elucidating the plant pathway to the microbial production strain – predefined deliverables, timelines, and scope will be determined jointly with you!

Experts:

Prof. Dr. Wolfgang Kroutil, Prof. Dr. Harald PichlerDevelopment status:

Status of the project proposal – Technology Readiness Level 2 (technology concept formulat-ed)Keywords:

Alizarin S, Anthraquinone Dye, Microbial Platform, Sustainable Diagnostics, Pathway Elucidation, Metabolic Modelling, HPLC-MS, Quantification, Green-Solvent Extraction, Scalable Purification, Technology TransferPicture: AI-generated