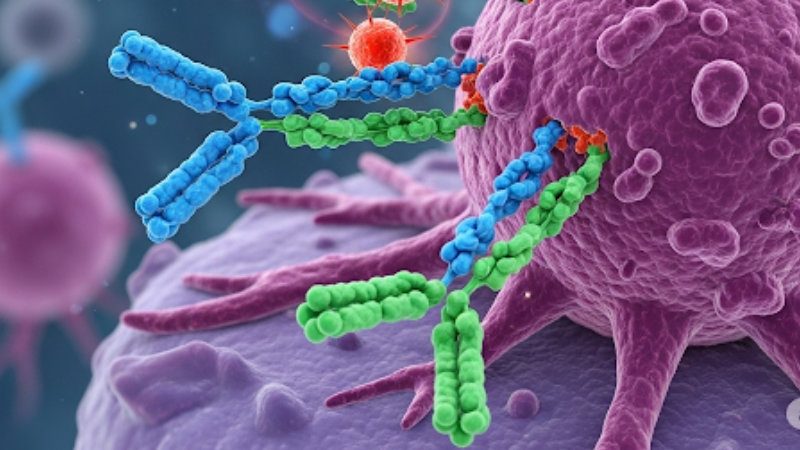

The surging demand for monoclonal antibodies (mAbs) is pushing the limits of traditional batch purification, plagued by inefficiencies and high costs. Enter continuous purification: a groundbreaking approach that revolutionizes efficiency, scalability, and profitability. Discover how this innovation is able to improve your biopharmaceutical production …

Background

Traditional batch chromatography for antibody purification is time-consuming and resource-intensive, leading to increased production costs and extended timelines. Continuous purification methods, such as continuous countercurrent chromatography and precipitation techniques, have demonstrated significant improvements in efficiency and scalability. These methods enable uninterrupted processing, leading to higher yields and consistent product quality.

Technology

Our approach integrates advanced continuous purification techniques, including:

- Multicolumn Countercurrent Solvent Gradient Purification: This technique combines the principles of countercurrent movement and solvent gradient batch chromatography, enabling high yields and purities even for challenging separations.

- Continuous Precipitation and Filtration: Implementing milliscale reactors facilitates the seamless integration of precipitation and filtration steps, streamlining the purification process and reducing processing time.

- Process Optimization: Employing in-line dilution conditioning (IDC) and periodic counter-current chromatography (PCC) to optimize ion-exchange processes, ensuring high purity and yield of antibodies.

Offer

Our offering to company partner includes:

Our offering to company partner includes:

- Comprehensive development of end-to-end continuous purification strategies, from initial process design to full-scale implementation.

- Support for pilot and industrial-scale process optimization, ensuring seamless transitions to large-scale production environments.

- Adaptation of continuous purification technologies to meet the specific requirements of diverse biopharmaceutical products.

- Provision of specialized training and knowledge transfer to ensure smooth adoption and operation of the technology.

- Exclusive access to intellectual property generated during the project, enabling partners to lead in innovation and commercialization.

Partner with acib to achieve a competitive edge in the biopharmaceutical market, not only for mAbs!

Experts:

Prof. Dr. Alois Jungbauer, Dr. Peter Satzer, Dr. Nico LinggDevelopment status:

Technology Readiness Level 4 (technology validated in lab)Keywords:

Continuous Purification, Monoclonal Antibodies (mAbs), Biopharma Production, Bioprocessing, Downstream Processing, Countercurrent Chromatography, Precipitation Technology, Cost-Efficient Biotechnology, Industrial Scale-Up, Pilotscale Development

Picture: acib